Composite plastic runway

Product Description:

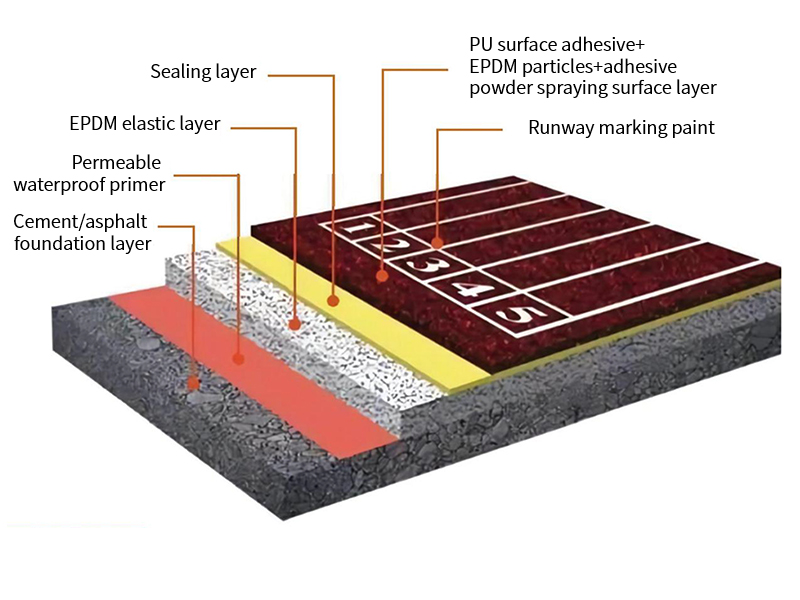

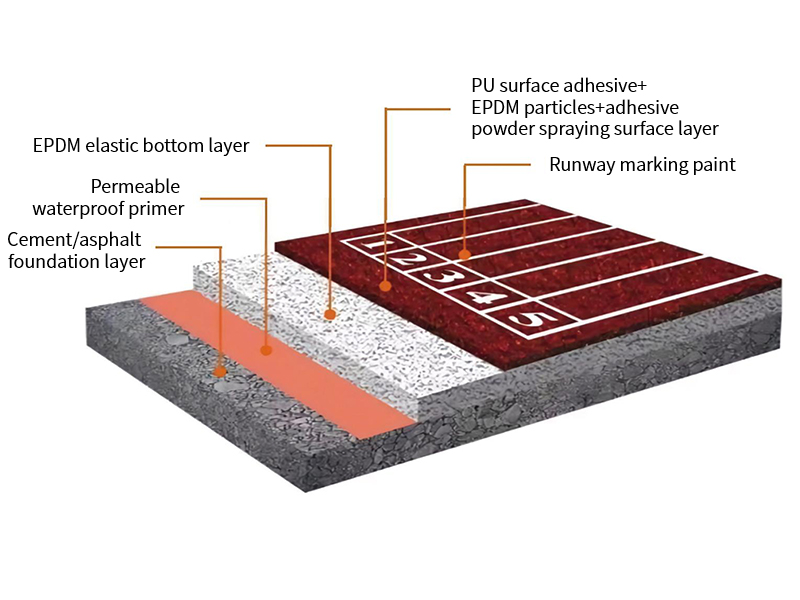

The performance of composite plastic runway is between breathable and hybrid plastic runway. The bottom layer is made of EPDM rubber environmentally friendly particles and a single component polyurethane adhesive uniformly mixed and mechanically spread, and then the runway PU material is used for sealing. The surface layer is a high-quality plastic runway with special patterns formed by spraying EPDM particles and polyurethane topcoat on the sealing layer.

Product features:

1. It has a PU sealing layer, which prevents rain and snow from entering the elastic layer of the plastic runway in high and cold regions. Rain and snow will not penetrate into the elastic layer of the bottom layer, making it the preferred product for sports venue construction in high and cold regions;

2. It has moderate elasticity and rebound force, which can reduce physical exertion, improve competition performance, and avoid sports injuries;

3. Moderate absorption of foot impact, reducing sports injuries, suitable for long-term practice and competition;

4. Low wear resistance, with a strong elastic layer and buffer layer, strong nail resistance, and will not be damaged by spiked shoes or starting gear, making it durable and durable;

5. The adhesive has excellent adhesion performance with EPDM particles and is not prone to aging;

6. The sealing layer is made of self-leveling material, which is flat and beautiful after construction, bright in color, non-toxic and environmentally friendly;

7.The cost of composite plastic runways is generally around 15% lower than that of hybrid plastic runways, which is economical and practical.

Construction process:

Foundation leveling and cleaning → Applying waterproof primer → Paving bottom layer → PU material sealing bottom layer → Spraying surface layer → Marking